TP-107 Series

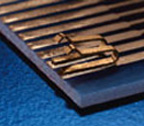

Components Corporation's TP-107 series of surface mounted, printed circuit test points allows engineers to take advantage of the convenience of field testing. The profile of the TP-107 readily accepts most commercially available spring clips and probes while providing a positive and secure anchor to the SMT board.

The Unique Flat Wire Design

To provide resistance to mechanical stress, the TP-107 achieves high-strength bonding through a unique forming process which doubles the surface area of the test points mounting. This is accomplished by forming the flat wire design in a spiral wrap on the mounting base, resulting in an adhesion to the solder pad which requires in excess of 18 pounds of force to dislodge the test point from its solder pad. For increased reliability and safety, the TP-107 surface mount test points are now available in silver-plated and matte tin finish.

Materials:

Contact Material: .015" x .040" Phosphor Bronze #510 Alloy, 1/2 hard

Finish: .0001 Matte Tin over .0001 Nickel or .0001" Min. Silver over .00005" Min. Copper

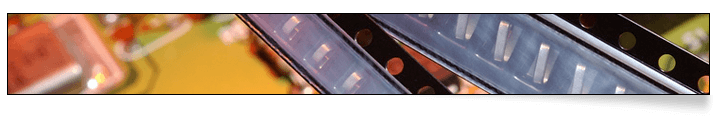

Tape Material: 12mm Wide;

Pitch: 4mm;

Conductive polycarbonate carrier meets ANSI/EIA-481 Standard

Reel Size: TP-107-02-1-T = 7" diameter: 1000 pieces per reel

TP-107-02-5-7 = 13" diameter: 5000 pieces per reel

Pad Size: .185" x .135"

U.S. Patent #5,747,740

Electrical

Maximum Current: 2.0 amperes